Pulse Handheld Fiber Welders

Pulse Laser Welder

Our new model handheld fiber laser welder machine is state of the art new technology.

Our laser welder is equipped with a new single Scanning technology allowing multiple types of welds from our new super light weight hand gun. The machines are used and sold extensively in fabrication industries and uses our unique soft start system for stable Aluminum welding with wire.

It has the advantages of simple operation, stable operating, perfect welding beam and and high welding speed. Welding in thin aluminum, stainless steel sheet, iron sheet, galvanized sheet and other metal materials can perfectly replace the traditional argon arc welding, Tig and Mig welding processes.

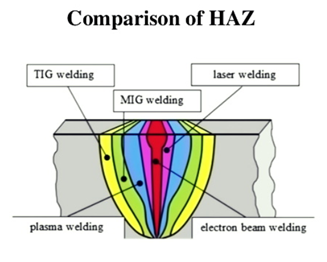

The HAZ is up to 200 times less affected. Handheld laser welding machine can be widely used in cabinets, kitchens, staircases, elevators, racks, ovens, stainless steel doors and windows guardrail, distribution boxes, stainless steel home and other industries complex and irregular welding process. Available in 240V 1.5KW solutions for 1 to 3mm welding, 2Kw 3ph for up to 6mm welding & 3Kw for up to 8mm welding.

This technology allows semi skilled employees to produce production welding. All PPE supplied. 2 Year Warranty on the source and 12 months on the rest of the machine. Ask about our custom safety shields to protect your workforce.

No deposit finance available.

CALL US FOR THE VERY BEST PRICES

Handheld Fiber Laser Welding Machine

| Item No. |

Max Output Power |

Welding Depth |

Welding Depth |

| FLW1500 |

1500W |

SS/CS 0.5-4mm |

AL 0.5-2mm |

| FLW2000 |

2000W |

SS/CS 0.5-5mm |

AL 0.5-3mm |

| FLW3000 |

3000W |

SS/CS 0.5-8mm |

AL 0.5-8mm |

| Note: If product thickness>0.3mm, you should add auto wire feeder | |||

| If product thickness is ≤0.3mm, no need for the auto wire feeder. | |||

Features

1. User friendly menu interface, simple operation, easy to understand and powerful.

2. The beam quality is good, the electro-optical conversion efficiency of the fiber laser is high, up to 25%, and the energy consumption is very low.

3. The machine has stable performance and long life, basically achieving maintenance free.

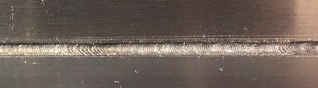

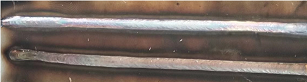

4.High aspect ratio, small weld width, small heat affected zone, small deformation and fast welding speed.

Applied Materials:

Suitable for welding many metals such as stainless steel ,mild steel, aluminum, galvanized sheet, copper and so on.

Specification

- Model:: FLW1500/2000/3000

- Power: 1500w/2000w/3000w

- Laser source: Raycus/IPG

- Raycus/IPG: 100000 hours

- Wavelength: 1100nm

- Operating voltage frequency: 50/60Hz

- Connector type: QBH

- Host power consumption: 6KW/6.5KW

- Welding penetration: 0.3mm-8mm

- Positioning: F120 mm

- Power demand: Single phase 240V (2/3kw needs 380V±5%),

- Output bond head type: Handheld Dual Scanning head

- Cooling mode: Integrated constant temperature

- Fiber length: 10 m

- Working temperature: 0~40℃

- Working humidity: 10~75%

- Environmental requirements: General workshop environment, humidity 5%-75%

- Floor area: 700mm x 1m

Welding Path

Continuous welding

Wobble welding

Wire filling welding

Spot welding Pulse welding

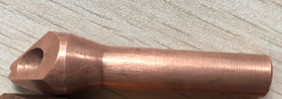

Four types copper nozzle

For inner angle

For outside angle

For cutting

For filling wire

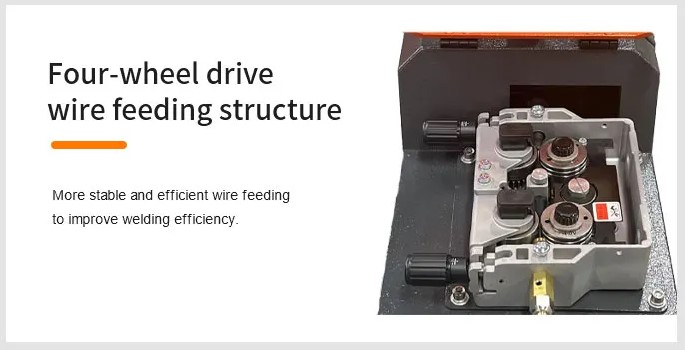

Auto wire feeder

Support wire material:Carbon steel, stainless steel, aluminium, brass etc. Support wire diameter: 0.8mm, 1.0mm,1.2mm

Weld wire

Carbon steel 0.8mm15KG/Roll,1.0mm20KG/Roll, Stainless steel wire 0.8mm/1.0mm, 15KG/Roll, Aluminium wire 0.8mm 6KG/Roll,1.0mm 7KG/Roll

Laser Source :Raycus or IPG

Lower power consumption, high photoelectric conversion efficiency. Better Beam quality than YAG laser ,Maintenance-free. 100,000 hours service life

Chiller

Brand: DoluyoBuilt-in water chiller come in a compact cabinet , save too much space,adopts special fiber laser welding head,with good cooling system

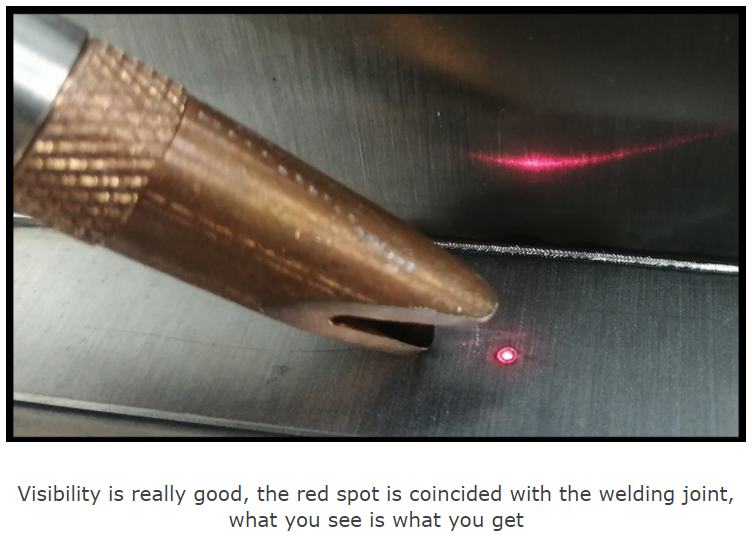

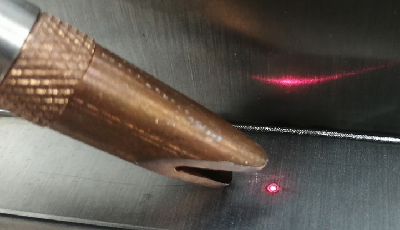

Fifth core advantage—Visable red pointing for easy locating

Visibility is really good, the red spot is coincided with the welding joint, what you see is what you get

Auxiliary Gas

Argon or nitrogen both ok. It is recommended to use argon for welding and nitrogen for cutting

Features

1. Humanized operation interface, simple intuitive operation, easy to understand and powerful.

2.The beam quality is good, the electro-optical conversion efficiency of the fiber laser is high, up to 40%, and the energy consumption is very low.

3. The whole machine has stable performance and long life, basically achieving maintenance free.

4.High aspect ratio, small weld width, small heat affected zone, small deformation and fast welding speed.

Applied Materials:

Suitable for welding many metals, such as stainless steel ,mild steel, aluminium, galvanized sheet, copper and so on.

Sample Photos